Sens0Light,

A step towards logistics 4.0

Sens0light : "The right SENSE with 0 unnecessary LIGHTS"

An existing technology from connected homes apply for the first time in logistics. Sens0light, lights controlled by real-time location of the warehouses users.

The statement

Commander nos services

Laissez-nous vos coordonnées et nous vous contacterons dans les meilleurs délais.

Electric over-consumption

It is thanks to our new look in the world of the industry that we have seen unnecessary lighting over-consumption in factories and warehouses. This over-consumption has dramatic costs...

Our solution

Sens0light

"Sens0Light helps warehouse managers to optimize energy consumption by reducing unnecessary lighting with an indoor positioning system of users (people and machines) which intelligently controls the lights"

This is our core value proposition ! But our ambition is to use this indoor localization system not only for lighting control but also for other applications... Discover the potential of our solution in the section "The Potential"

Our technology

Real-time location of warehouses users for a smart lighting control

Sens0ligth does not reinvent the wheel of the technology, but it gathers three mature technologies to make the supply chain greener.

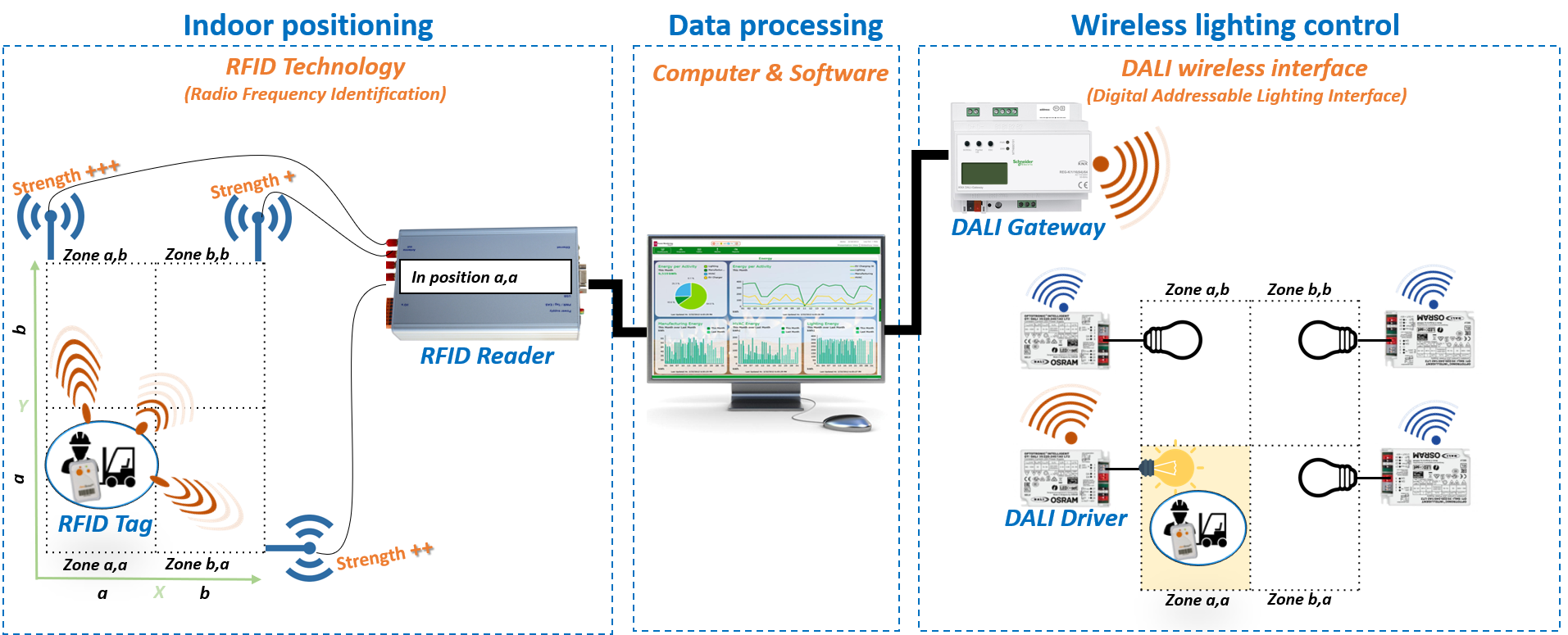

Our technology = three steps :

- I. Indoor positioning of the users in the warehouse : Each user (employee or machine) of the warehouse is equipped with a RFID tag, such as a badge, a bracelet, a chip or which can be integrated in the safety shoes. This tag emits a signal, this signal is detected by several antennas in the warehouse. Depending the strength of this signal (according to the position of the user), the RFID reader calculates the position of the users in the warehouse (coordinates). This is the RSS method (Received Signal Strength) of the RFID technology.

- II. Data processing: The warehouse is theoretically divided into several zones, so the computer collects the data from the RFID reader. These data are the real-time positions of the users in the warehouse. A software inside the computer sends the orders to switch on / off the lights of the different zones according to the positions of the users

- III. Wireless smart lighting control: The control orders of the computer are sent to the DALI* (Digitally Addressable lighting Systems) gateway, which acts as a wireless contractor to control the lights. A DALI driver is needed for each led because it enables the individual control of the lights. The DALI is an electrical interface protocol that enables the exchangeability of dimmable ballasts from various manufacturers. Another feature of DALI is the ability to diagnose problems, such as lamp brightness, lamp failure and lamp type.

The logic behind the technology : If someone is detected in a zone, the light is switched on. So if there is no one, there is no light!

The potential

The potential of our technology

Our innovation enables to intelligently manage your lighting system in order to reduce your unnecessary energy consumption. Our technology is incremental so it has many other possibilities without any efforts :

Function 1

Today we provide a smart lighting control of your warehouses, this is Sens0Light

Function 2

We will be able to provide risk prevention with an accelerometer and a gyroscope to detect falls or unusual locations of the users

Function 3

In the final version, we will be able to send real-time data concerning internal warehouse flows of people & machines

All these data will be exploited to optimize logistics flows to finally reduce operating costs

Challenges

Industry 4.0

Industry 4.0 (or industry of the future) is a new generation of connected, robotic and smart factories.

With the digital revolution, limits between the physical and digital world are shrinking to give life to an interconnected 4.0 factory in which people, machines and products interact. Industry 4.0 is a challenge and a real opportunity for industry.

Industries face this challenge and we know that every industrial investment must be profitable

Sens0ligth gives access to the Industry 4.0